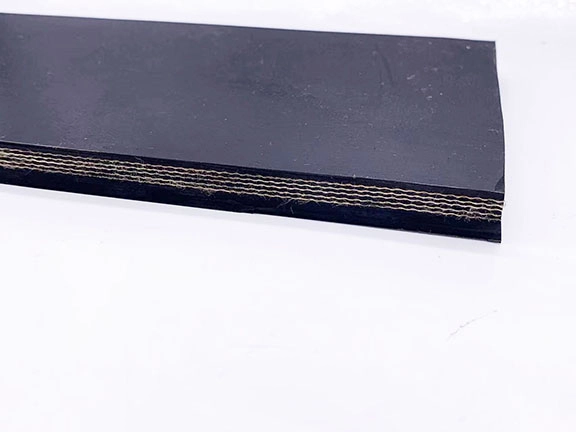

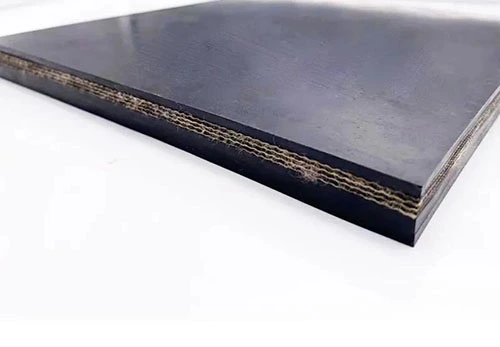

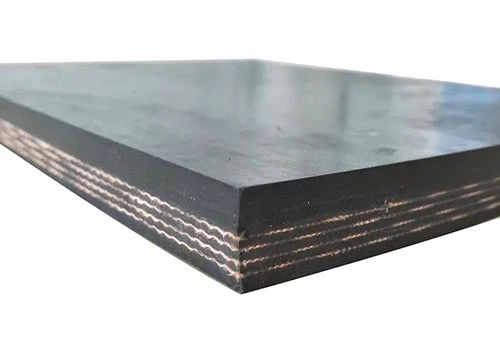

Top Cover:

The top cover is designed to safeguard the carcass from various service conditions. It provides robust protection against damaging elements such as oil, heat, and abrasion, ensuring the longevity and durability of the belt in harsh working environments.

Skim Rubber:

Positioned between the plies, the skim rubber is specially compounded to offer superior adhesion. This layer plays a critical role in preventing ply separation, thereby maintaining the structural integrity of the belt during operation.

Textile Fabric (EP, NN, CC):

These materials are chosen for their exceptionally low stretch characteristics and excellent troughability, which enhance the belt’s performance and adaptability to various conveyor configurations.

Bottom Cover:

The bottom cover is designed with a focus on abrasion resistance and flexibility. It provides a durable wearing surface that withstands continuous contact with pulleys and idlers, thereby extending the operational life of the belt.

Features of Fabric Conveyor Belt

-

Enhanced Performance:

Offering high tensile strength, durability, low stretch characteristics, and flexibility, these features ensure reliable and efficient operation in demanding conditions, making the fabric conveyor belts suitable for handling heavy loads and high-stress environments. -

Various Cover Grades:

Abrasion-resistant, heat-resistant, oil and chemical-resistant, and flame-resistant covers enhance the adaptability of fabric conveyor belts. These specialized covers provide additional protection and extend the belt’s lifespan, catering to specific industrial requirements. -

Versatility:

Fabric conveyor belts offer a wide range of applications across different industries, ease of installation and maintenance, and compatibility with various troughing configurations. Customizable designs allow for tailored solutions to meet specific operational needs, making them a practical choice for diverse applications. -

Environmental Friendliness:

With options for biodegradable and recyclable materials, energy-efficient operation, and eco-friendly manufacturing processes, these belts contribute to sustainability efforts and reduce environmental impact, aligning with modern industry standards and practices.

The Role of Textile/Fibers in Fabric Conveyor Belting

Textiles or fibers play an essential role in the structure and strength of conveyor belting systems. Common textiles used in the production of fabric conveyor belts include both natural and synthetic fibers, such as cotton, wool, nylon, and polyester.

-

Cotton and Wool:

Cotton and wool fibers are characterized by moderate strength, high elongation, low cut and abrasion resistance, moderate temperature resistance, and low mildew resistance. These fibers are generally used in lighter-duty applications where extreme strength is not required, but flexibility and adaptability are beneficial. -

Nylon and Polyester:

Both nylon and polyester share similar characteristics, including high strength, high elasticity, moderate elongation, high cut and abrasion resistance, and high mildew resistance. The primary difference lies in their temperature resistance properties. While nylon is more resistant to heat, polyester offers superior cold resistance, making it a better option for colder environments. These fibers are ideal for heavy-duty conveyor applications that require higher tensile strength and resistance to wear and tear.

The Manufacturing Process of Fabric Conveyor Belts

Fabric conveyor belts are manufactured through a detailed and multi-step process that ensures high quality and performance standards. The typical process includes the following stages:

-

Raw Material Selection:

The quality of the raw materials (fabric, rubber, etc.) is critical in determining the overall performance of the conveyor belt. The selection of appropriate fabrics, such as polyester, nylon, or cotton, is essential for achieving the desired tensile strength, flexibility, and durability. -

Calendering:

Calendering is the process of passing the raw materials (rubber and fabric) through rollers to bond them together into a cohesive sheet. This process ensures uniform thickness and consistency across the entire length of the belt. -

Vulcanization:

Vulcanization involves heating the rubber at a controlled temperature to improve its elasticity and strength. This chemical process helps to solidify the rubber, making it more durable and resistant to wear and heat. -

Covering and Cutting:

The prepared fabric is then covered with a layer of rubber to form the top and bottom covers of the belt. Afterward, the belt is cut to the required length and width, ready for the next step. -

Splicing:

The splicing process involves joining two ends of the conveyor belt together to form a continuous loop. This is typically done using specialized equipment and adhesives to ensure a secure bond. -

Quality Control and Final Inspection:

Before being shipped out, each conveyor belt undergoes a thorough quality control process. This includes checking for defects in the material, ensuring the proper adhesion of the layers, verifying the overall dimensions, and confirming that the belt meets all performance specifications. -

Packaging:

Once the belts pass the final inspection, they are packaged for shipment. The packaging is designed to protect the belts from damage during transportation.

Tiryuk Co. employs a team of highly skilled professionals who meticulously monitor each step of the manufacturing process to ensure the highest standards of quality. With state-of-the-art manufacturing facilities and cutting-edge technology, Tiryuk Co. remains committed to delivering fabric conveyor belts of superior quality to meet the demands of a diverse range of industries.